|

|

Post by seeshell on Nov 26, 2012 13:45:58 GMT 10

Hi HD We're not going to reinstate canvas, but I can appreciate its function as well as its appeal.  We're just going to paint using the specialised waterproof system. There's quite a few examples of good canvas jobs, including by Kaybee, and Fisher in recent memory.  Cheers Seeshell |

|

|

|

Post by Franklin1 on Nov 26, 2012 14:35:09 GMT 10

G'day seeshell, I'll also join in with the "Wow!, what an amazing job!!"-crowd   One thing I'm confused about is the previous Bote-Cote coating you applied, versus the recent Norglass coating you applied. Why is it necessary to apply both products?? What does the Norglass do that the Bote-Cote doesn't? (asks he who has only been using B/C and suddenly thinks, "Oh-oh"  ) ps. I know you love technical questions (tee hee  ). cheers, Al. |

|

|

|

Post by seeshell on Nov 26, 2012 16:08:31 GMT 10

Hi Al Thanks for the moral support!  And how well you know me - I love technical challenges. ;D Our first forays into paint (refer back to the paint trials) meant that we needed to prepare the wood with something to make sure the paint would stick - without some sort of embedded treatment everything else just seemed to slide off. We initially looked at the bote-cote system which involves the resin, then primer then paint. Once the test resin was on, everything seemed to stick fine - but we only got as far as patch testing not putting it all over. But to be sure we had no trouble with incompatible products we decided to go with one manufacturer's system of sealant, primer and paint. Bote-coat resin was absolutely great - and has the same properties as the Norseal product in that its designed to make things waterproof. The Norseal product wicks into the wood rather than sitting out on the surface like the bote-cote but they do much the same job. You would use one product or the other, not both. In terms of primer, either company have a very good option to choose from, so that did not really drive our decision-making. The clincher for us was that Norglass would tint the paint to any Dulux colour. When we approached boat-cote they were not keen, and really didn't want to entertain custom tinting. And I'm afraid *I* was not keen to entertain painting our van in one of 16 marine-coloured shades.  Additionally, Norglass had a filler and epoxy as part of their system, which was also chemically compatible. Probably we've worried about it all for nothing, but I think I'd cry if we had to start over - so better safe than sorry! I think either system would work well for waterproofing and getting a lovely finish (we shall see!), but the Norglass product just offered us a little more artistic license! Cheers! Seeshell |

|

neilncheryl

Full Member

Make God laugh, tell Him your plans.

Make God laugh, tell Him your plans.

Posts: 324

|

Post by neilncheryl on Nov 26, 2012 19:28:53 GMT 10

Hi Seeshell

I used the Norglass product to treat the framework in my van after a recommendation from a friend who has used it with boat repairs. Very happy with it.

|

|

|

|

Post by seeshell on Nov 29, 2012 21:28:25 GMT 10

Good evening All The work on the Blue Flyer continues with the rebuilding of the hatch. The original hatch had suffered somewhat from having a skin of aluminium applied to it. There were blind rivets buried in the wood of the hatch which meant we’d spend as much time trying to dig them out and bog and sand as build a replacement. Additionally, because of the way the wood was running up and down and not along the length of the hatch, it made the sides weaker. Every time the hatch was laid down it actually flattened out significantly. It only had one central rib running the full length as well – meaning there was little support for the ply skin. Oh, and it wasn’t square…of course! The old one was laid on its side and a template of the arc was cut, and then tested on the roof. Rather than copying the other side, we copied the new arc (to help make the new hatch more uniform). Rather than laying the support along the length we put them across the frame.  The whole hatch was made with lightaply – meaning it weighs only about 2/3 of the previous hatch. And less than half of the hatch when skinned in aluminium! The frame was clamped and glued with Staybond epoxy, and we will glue the skin to the frame over the next few days in readiness to coat it in the Norseal wood preserver. We’ve ordered many lengths of the T1 J-mould from Capral and will test fit it to the van this weekend to mark up all the nails to avoid before we lose sight of them under the primer. Coincidentally this month’s Vintage Caravan magazine had an article on bending J-mould…how timely! But the biggest challenge is getting home 6m lengths of rope track. A handy hint for transporting your moulding is to mount a piece of poly pipe to the top of the car (ensure the ends are supported and tied to avoid bouncing). The lengths can travel safely inside, without getting damaged. Cracking on… Seeshell |

|

|

|

Post by hilldweller on Nov 30, 2012 7:40:53 GMT 10

Sounds like it's all go at your place  How big is that hatch? Looks huge! |

|

|

|

Post by seeshell on Nov 30, 2012 13:46:07 GMT 10

Hi HD Our hatch is 995mm wide and 2430mm long - it's a monster all right! You can see why it being lighter is a benefit. The old one was a bit hard for me to lift when standing on tippy toe.  Cheers Seeshell |

|

|

|

Post by Roehm3108 on Nov 30, 2012 17:15:11 GMT 10

|

|

|

|

Post by seeshell on Dec 1, 2012 17:20:43 GMT 10

Hi All Today's Achievements- Another bl**dy day of sanding.

- Finding more little things to bog.

- Peeling the tape off the window trim in irregular 2cm squares (put on in anticipation of painting in time for Cowra, now nearly fused on!).

- Wiping the sticky off with turps, then wiping off the turps with metho.

- Blue taping up the windows again in anticipation of primer tomorrow.

- Gluing the skin on the hatch.

- Find out I got High Distinctions for both courses I took this semester for my Masters.

A hell of a day - both of us really dog tired! Weekly update pictures to follow tomorrow. Cheers Seeshell |

|

|

|

Post by cobber on Dec 1, 2012 18:07:53 GMT 10

G'day seeshell, Congratulations on all your achievements ...... Six in one day  ....the seventh probably took a bit more effort......aye ? Keep at it  Cobber. |

|

|

|

Post by seeshell on Dec 2, 2012 18:15:18 GMT 10

Hi All The weekend work continued at a good clip. Getting Ready For PrimerToday we managed to finish masking up, including the Jones Wheel assembly. Cling film worked quite well – as do garbage bags.  We also worked some magic on our UberHatch. Of course the easiest way to paint is through it, so we covered the central fly wire with clear plastic, and made two chutes at each access end. This allowed the hubby to go through the chutes with the paint sprayer to get to the roof. See him in situ here:  I got to stand inside the van and hold it bunched up around his legs.

Painting

Today, we painted three coats of shipshape primer thinned up to 30% per instructions. It went on just fine, and of course neither of us have really done something of this size before. The old hatch got used as target practice to set up the size of the fan of spray from the gun, as well as technique!  Then it was all systems go. We had a bit of a system: I did the paint and chemistry (mixing, timing), and generally filled the sprayer, moved the ladders, untapped and retaped things following entrance and exit from the van door…Gopher Work. Hubby (being taller and with Monkey Arms) suited up for the spray work.     Finishing Up Finishing UpAaron got quite excited and channelled Bruce Banner at the end of the day’s painting.  The Waterproofing Treatment The Waterproofing TreatmentAs you know we painted the body with Norseal Wood Treatment. We had some leftovers in a bucket, and today we opened it up. The contents were strange! It was a bit like rubber, bouncy but a little crumbly:  So that is what happens under the surface of the wood! I can see how that would make it watertight. A very different product than the Bote-Cote which is hard and resinous, and sits on the surface – but the advantage of Bote-Cote is that it certainly helps cover all the grain and any other issues, making for a very nice finish. Norseal doesn’t really do that, and requires the high build primer to account for those imperfections. So we are going to go over our primer again to make sure we get enough on to fill the grain to allow for a smooth sandout (see The Results). The ResultsWe got a good coat on the van (nearly 8L with wet on wet technique) but we can still see grain and places where the patches were. Both of us agree that what it needs now is ANOTHER SAND and then a thicker rollered on coat of the primer to fill the last of the grain.  The consistency of our primer was probably too thin but it was our first go at it, so we were happier to do more coats than have heavy runs while learning what to do. At the end of the day it’s satisfying to see it in primer, even if there is probably another weekend of working and sanding it at this stage to get it smooth enough for colour. We were aiming to take it away painted for Chrissy but we’re agreed that there’s no point rushing now when we blew our Cowra deadline by about 8 months!  The hatch needs the ply routed to the edge of the frame and for the wood seal to be applied...maybe later in the week!  Exhausted, but happy! Seeshell |

|

|

|

Post by DC3Td on Dec 2, 2012 19:51:25 GMT 10

Hi guys. And a great day was had by all, as they say. It`s a big job,doing all the masking & tapeing making sure all bases are covered.Then the main job of spraying.Fantastic effort.Already looks the part. gordon

|

|

|

|

Post by humpyboy on Dec 2, 2012 20:35:08 GMT 10

Wow making some serious progress with it now lookin good.

|

|

|

|

Post by Don Ricardo on Dec 2, 2012 22:09:20 GMT 10

G'day Seeshell,

I'm really enjoying your posts about the Blue Flyer, and it's great to observe your progress. No need to apologise when you post a bit of detail about your work either - I'm sure that your explanations and the pics help a lot of people, and will help others in the future when they read the story of your van.

Well done, on the items you put a tick against on your list yesterday. Particularly the last. Been there done that, and Cobber's assessment is definitely correct!

Don Ricardo

|

|

|

|

Post by seeshell on Dec 3, 2012 6:47:44 GMT 10

Hi All

Thanks for the messages and encouragement about the Blue Flyer. We really appreciate everyone's interest in our project.

As many of you would know from your own projects, it's good to make a log of what happened - it's astounding how quickly the little details are lost to the mists of time!

We really value the the information from the previous owners about her build, holidays, various colour schemes and refits - it makes her "more human" if that makes sense. We hope future conservators will also love to have pictures and and evidence of her refurbishment as well from the time we have her.

Finally, when you have particularly sore arms from sanding, your hair is full of paint, and your fingers are stinging from thinners and cuts, the support from other like-minded crazies is just the thing to raise the spirits!

Thanks very much,

Seeshell

|

|

|

|

Post by hilldweller on Dec 3, 2012 11:33:02 GMT 10

Wow it's gone from brown to white! Can't wait to see it with topcoat  Congrats on the academic results too! |

|

|

|

Post by hilldweller on Dec 3, 2012 11:37:40 GMT 10

The hatch needs the ply routed to the edge of the frame ... Could you explain what that means? I am trying to work out what a router does    Yours confusedly |

|

|

|

Post by seeshell on Dec 3, 2012 13:01:05 GMT 10

Hi Hilldweller We cut the ply top for the hatch frame about 3mm wider on all sides so a bit hangs over all around. Using either a laminate trimmer or router and a collared bit, you can make a perfect fit easier than trying to cut a piece with a saw/jigsaw. In our case, the collar on the bit will run along the frame and the bit will cut off the 3mm of excess ply.  Cheers Seeshell |

|

|

|

Post by hilldweller on Dec 3, 2012 14:02:41 GMT 10

Ah! Many thanks. Think I might need one of those when I (eventually) get onto Mabel  . |

|

|

|

Post by seeshell on Dec 9, 2012 11:48:03 GMT 10

Hi All Today we did two things: work out how to get the right level of finish with the primer, and also sand and bog the hatch in readiness for the resin. As you might remember, after our three coats of thinned primer last week, we were still seeing too much grain and you could see where the bog patches were (since they were perfectly smooth!). Today we sanded up a section of the van three ways to plan out how to proceed: - with the Air Sander

- significant sanding by hand

- a light scuff off by hand

Then we mixed up some of the primer, unthinned, and rollered it on over the test sections. There was an advantage in sanding of course, but going heavy on the sanding over just knocking the peaks and gloss off didn't really add any advantage. The advantage of the rollering was we were able to push the thicker primer (thicker than used for spraying) into the grain and cover some blemishes. Already the finish is more even. Another scuff coat followed by another thick coat of primer, then a good sand off will give us a colour-ready surface.

Moral of the Story:If you already have a fairly good and even surface, spraying is a good option for primer. For example, where the wood grain was filled with bote-cote or bog, the spray finish was excellent. Advantage is that you can put multiple coats on at a time - 3 or more wet over wet because you're not disturbing the surface with a brush or roller. If your surface is uneven, or you have a lot of grain to fill with primer, it would seem you're really best to roller it on. The unthinned paint is better at resolving minor blemishes and grain, but the disadvantage is that you will need to wait 2-3 days between coats to sand before doing follow up cover. You will need 2-3 coats. Looks like given the timing, we will be going away for Christmas with the van in primer only. But very happy to have worked out how to get the best finish we can.  Cheers Seeshell |

|

|

|

Post by jenniewren on Jan 19, 2013 12:02:44 GMT 10

OMG.....I sure have missed a lot Carly!! Incredible....I have read every word & as usual with your posts...awestruck. You are thorough, informative, motivated like crazy & put me to shame! I need to repaint Colin/Scarlett very soon...which is why I have been scurrying around the site...have been unbelievably busy the past 18 mths with work, weddings, funerals, overseas a few times...you name it (and then we were hit with a wedding at Christmas.... our daughter will be married this coming Nov & so I have been concerntrating on her wants as far as organising a "vintage/country/CWA type wedding affair to be held on her soon to be in-lawns property in Bendigo-the normal stuff a wedding entails...making mason jar candles (200 of the suckers) and vintage fabric bunting (150 mteres of that! Why, why, why....Har!) grrrr --- we have been just too exhausted to think about repainting til now! But the weather has finally improved!! So I have to find the time to paint him/her! BUT...Ummm...have I missed something with your Olympic.....have been searching for something to give me a clue...anything...but I haven't found it yet! Did you sell it for "the blue flyer"? Which I LOVE but I thought the fibreglass little number was gorgeous also! AND no I still haven't gotten around to doing something with the old annex....far out....not enough hours in the day! But I admire and congratulate you both on such determination to have your beautiful van completed.....awesome work you have done. Finished yet? Finished yet? I was thinking of selling Colin/Scarlett.....slap me....what was I thinking! You & getting back into the forum have inspired me to get my butt into gear, stop procrastinating & repaint & take him/her on another jaunt before the weather turns! Have you any recent photo's if your vv is finished? Best wishes.....J

|

|

|

|

Post by seeshell on Feb 12, 2013 15:29:35 GMT 10

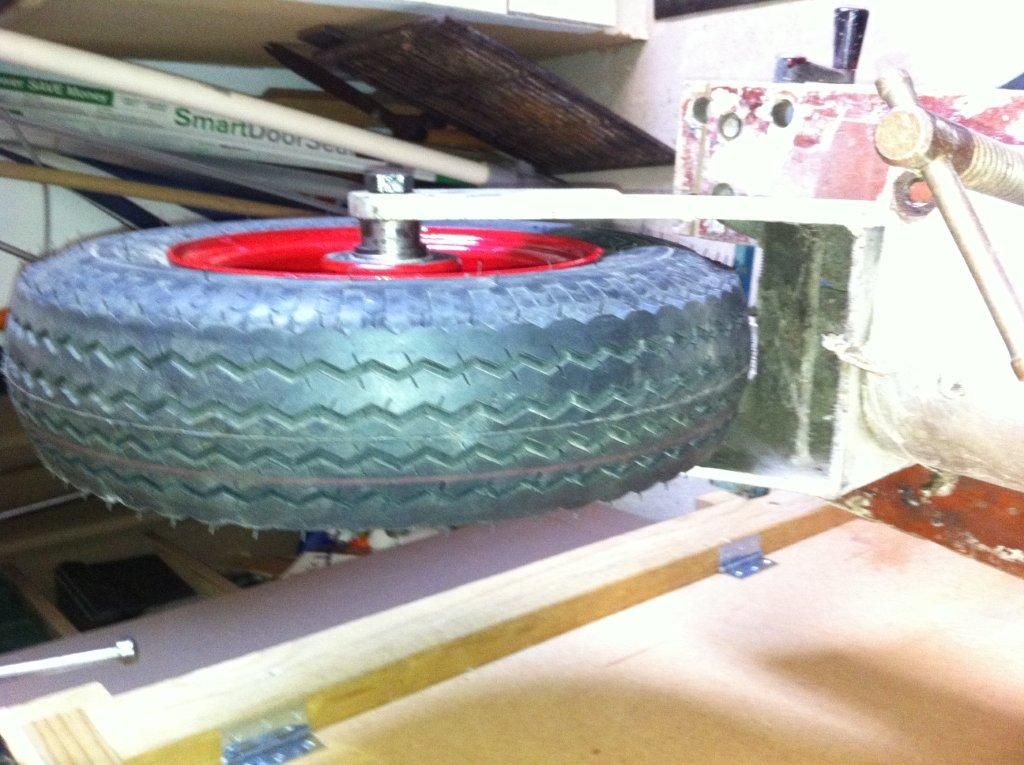

Hi All Lately restoration of The Blue Flyer has been somewhat derailed by the arrival of the Chrysler tow car and work. But we have managed to get on to the Jones Wheel to make it functional again. It's been a surprising amount of work: - The wheel was sanded and then sandblasted.

- The wheel was powdercoated to match the rims.

- We sourced thinner road going tyres.

- We had the wheels fitted to the rims.

- We sourced the bearings.

- We had the rod drilled out of the axle.

- We had a new wheel bolt fabricated.

- We reassembled and test fit the wheel to the assembly.

Here's a picture of the test fit. Looking good - so it's time to take it apart, sand and paint the assembly with hammertone, and source some chromed bolts for the wheel.  Here it's easier to see the improved clearance achieved with the slightly thinner tyre. The previous owner had put on a 8/5.7 which was probably too wide, since it bulged over the rim slightly. When you put the wheel on full tyre pressure, and headed down a hill (with the Jones Wheel bearing weight), you could hear it squeaking as it rubbed on the frame!  We haven't changed the spacers, length of the axle, or the rim, and have faithfully replaced the bearings. Based on the edge of the rim and spacers, I think the 8/4.8 we sourced is much closer to what would have originally been on there to begin with. Cheers Seeshell |

|

|

|

Post by hilldweller on Feb 16, 2013 12:56:58 GMT 10

Looks good. It's amazing how many little steps are involved in doing something like that! Love the colour  |

|

|

|

Post by seeshell on Feb 19, 2013 17:53:58 GMT 10

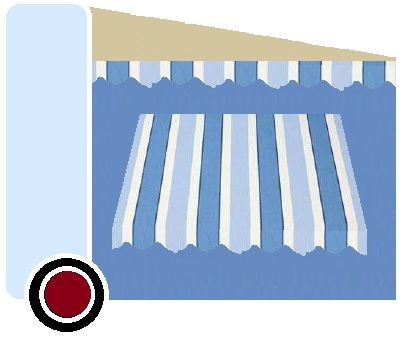

Hi All A few more jobs on the go - including trying to get the awning underway. Here's roughly what it will look like (if vans could be drawn as stick figures):  The roof will be a heavy waterproof canvas in a dark sand colour, and the walls are lighter canvas in a cornflower blue. The stripes are from the Dickson Orchestra range - stripe pattern is blue Hardelot. The wall colour is almost a perfect match for the flash that will go on The Blue Flyer. I went in with different things in mind than what you see here - but the little old gent who owns the business had other ideas. He's from Malta and has been in the canvas trade since 1951. "No you don't want that colour for the roof - everyone looks yellow and sick in its light. Sand is better. NO not white - too dirty, and hot." "No, the stripe is too much. You should do this colour, it's discontinued and cheaper. Your husband will thank me!" Quite the character but he knew EXACTLY what I meant when I talked about wall hooks, lace up sides, and the need for the roof to be rounded. I'm feeling good about it even if I can only understand every other word he says. We got to talking and he mentioned he has some marconi fittings. Let me know if you need some and I'll pass on his details. Also, sent the hooks to the polishers. That will get them back to new. The porthole has gone as well... Hopefully it cools down - we need to get back to sanding and painting to make the Mexican tour! Cheers Seeshell |

|

|

|

Post by jenniewren on Feb 19, 2013 21:28:16 GMT 10

Mr Malta canvas gent sounds like my kinda guy!!! Nothing like a person who knows their trade! Like the colours Seeshell.....but I am a bit partial to blue & of course those red wheels on your vv are really gorgeous!

|

|