|

|

Post by shesgotthelook on May 6, 2013 9:46:00 GMT 10

As this is an often discussed topic, I thought I would create it's own thread. If Franklin 1 could share his steam bending pics & trials & errors of making corners that would be great. I thought I'd start with this lovely article from 1939.    |

|

|

|

Post by Geoff & Jude on May 6, 2013 18:31:27 GMT 10

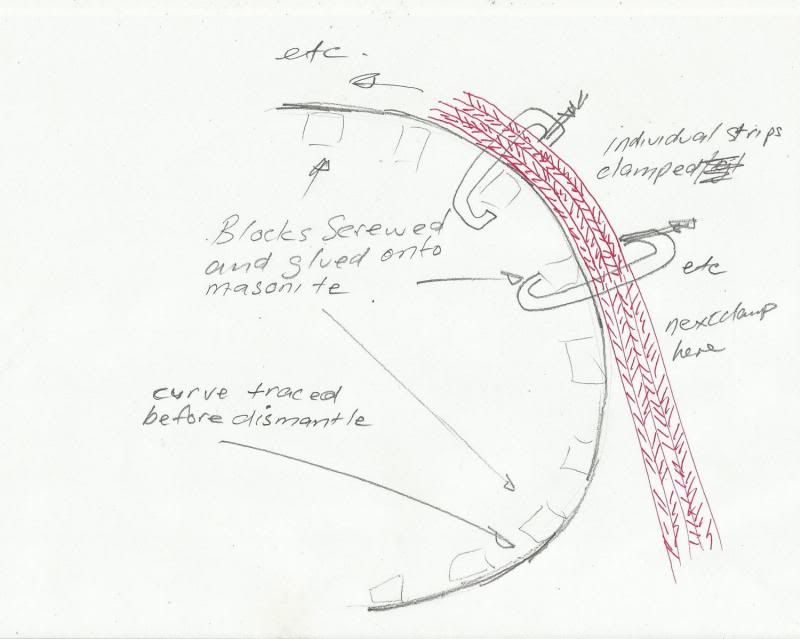

back in 2006 when we did some restoration work on the roadmaster, we needed to replace the main timber frames on all the curved corners. we decided to reproduce the shape by making laminated bends from meranti. in a nutshell, we traced the shape onto masonite, glued and screwed blocks to the traced shape then laminated meranti strips by clamping them to the blocks. firstly we ran 10mm thick meranti through a thicknesser to about 5mm so it would bend freely. then we liberally coated each side of the timber with pva glue, put some paper/plastic down on the template so the frame didn't stick to it, then progressively clamped and bent the multiple layers to the shape.  you need to progressively clamp to each block so the individual timber strips can slide on each other as the bend forms. you'll also need to make sure your strips are at least 500-700mm longer than the total bend required so the shape can be trimmed. it worked a treat and the final shape was almost exactly the same as the original and the lamination process makes the bend unbelievably strong. i've left the offcut below on our front stone wall since 2006 to keep an eye on the quality of the pva glue, and although the timber is now green with weathering, the glue is as good as the day we formed it.  hope this adds to what al has said in his newcastle thread and helps to explain the laminating/bending process. geoff 'n jude |

|

|

|

Post by Franklin1 on May 6, 2013 21:40:27 GMT 10

Ok, here's my contribution about bending timber... Dry bending:Dry bending is when you use dry solid timber (as opposed to plywood) that is readily available from your local timber supplier. You need to know the radius that you are bending the timber around. Then you can calculate the maximum thickness of timber that will bend around that radius. The general formula for softwoods is: Maximum thickness = radius divided by 100 If the radius is 500mm, your timber should be a maximum thickness of 500 divided by 100 = 5mm. If you need a final thickness greater than 5mm, you laminate as many 5mm strips together as you require to get the final thickness (eg, for 30mm you need six of the 5mm strips glued together). Bending solid timber is thickness dependent. Doesn't matter about width or length. If a narrow strip will bend around your radius when it's 5mm thick, then a 300mm-wide board of the same timber will bend around your radius when it's 5mm thick. Wet bending (steam bending):Best to read the posts in my thread about my Franklin van: Franklin1...finally she begins! Skip down to Repy #8 and read from there, and you'll see what happened when I tried to steam bend some timber. (Wonder whatever happened to that van?   ) Also some useful info from reddo in this thread: bending timber moulding etccheers, Al. |

|

|

|

Post by shesgotthelook on May 8, 2013 14:05:58 GMT 10

Well my persistent little big boy has managed to bend the meranti. Dad cut some notches in it & I think they soaked it with wet towels before steaming.

He says it does spring back a bit but assures me he can fix it in the right place.

Grr xxx@@@@@!!!!!!!!!

ok, off to find that post about why photos show up as deleted

|

|

|

|

Post by shesgotthelook on May 8, 2013 16:05:42 GMT 10

|

|

|

|

Post by shesgotthelook on May 8, 2013 18:18:02 GMT 10

|

|

|

|

Post by Franklin1 on May 8, 2013 19:01:14 GMT 10

What Dad has done to the timber is known as "kerfing". If you cut plenty of 'slots' in the timber, it can be bent around curves. The more slots, the tighter the radius it will bend around. The cuts need to be deeper than what Dad's done, and there needs to be more cuts per foot of timber. Former member 'myvan' has a Newcastle van, which was rebuilt by a carpenter who used the kerfing method to bend the framework. If you go down to Reply #7 in this thread, you'll see what it looks like: Pink Poodle My 1951 Bondwood re buildFor best results with the kerfing method, the slots need to be filled with glue so they make the timber "solid" again. Don't give up!! ;D cheers, Al. |

|

|

|

Post by shesgotthelook on May 25, 2013 12:06:04 GMT 10

Hughie's steam bender  Uploaded with ImageShack.usthe water drum would be sat on a supporting frame, not directly on top of the gas ring, but pic is just for demo.  Uploaded with ImageShack.us Uploaded with ImageShack.us |

|

|

|

Post by shesgotthelook on May 25, 2013 12:08:11 GMT 10

Here is his ply built corner but he's worried it's too flexible & not strong enough  Uploaded with ImageShack.us Uploaded with ImageShack.us |

|

|

|

Post by Franklin1 on May 28, 2013 21:07:54 GMT 10

G'day sgtl, That's a very good effort for a first-time go at laminating plywood strips. I would only deduct a mark or two for the air gaps between the layers, but they can be filled with PVA if he hasn't already fitted the piece into position. Don't worry about the apparent lack of strength. It'll do the job fine. It's not the only piece of timber holding the van together, and it's a darn sight better than the bit that was in there previously. To improve any future attempts, he needs Mum to shout him a few more clamps so he can clamp the strips at closer intervals. The aim is to create a "solid block" of layers with no noticeable air gaps between the layers...  You would probably have seen the photos in my thread where I laminated 7 strips of ply around the walls. It just goes to show you can never have too many clamps   ...   Good effort also on the steam box.   My only query is about how the timber is kept off the bottom of the box so the steam can get into the timber on all the faces. Cripes, the young fella will know more about steam bending and laminating at 16, than I did when I was 50!   ;D Good on him! You tell him I reckon he's doing a great job!   cheers, Al. |

|

|

|

Post by shesgotthelook on May 28, 2013 22:25:02 GMT 10

Thanks for all your advice thus far Al, very much appreciated. I don't know about space around the timber to get the steam through all of it, will have to quiz him in the morning. Maybe this is one of our downfalls  Caught him attempting repairs on a vintage tractor on the weekend & told him to get back to his caravan  |

|