|

|

Post by hilldweller on Mar 16, 2012 17:03:17 GMT 10

Sorry about all the questions, but I've been looking at pics of cupboard doors and a lot of them have an almost 3D look to them I really like - thick-ish timber with a curve to the cut edge, and nice glossy paint.

So what are they made from (the hinged ones, not sliding ones), how thick is it and is there a trick to getting a nice even edge? Many thanks, again.

hilldweller

|

|

|

|

Post by humpyboy on Mar 16, 2012 17:49:30 GMT 10

Your choices would be Ply or Masonite I'd say with an internal frame that you could knock up out of pine, as for your round edge I'd go with a router or if you have the time  take most of the waste away with a plane then finish off with sand paper using all available elbow grease and finger skin ;D Someone who is more serious will be along soon  |

|

|

|

Post by humpyboy on Mar 16, 2012 19:40:17 GMT 10

Must admit I've never looked as I've never needed it  , I usually use them plug in the wall things, makes life so much easier ;D |

|

|

|

Post by Franklin1 on Mar 16, 2012 20:13:57 GMT 10

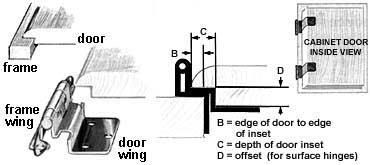

G'day hilldweller, The typical caravan door from the old days is an "inset door" (and probably goes by other names as well). The construction method is known as "drum built" because it resembles a (bass) drum with two skins and air in between. The door is often made of three layers. The outer skin is typically masonite or ply, as humpyboy said. The middle layer is a very thin timber frame, and the inner layer is thin plywood. The outer layer overlaps the surrounding framework by about 3/8". See the picture in the top left of this diagram...  You can use two types of hinges in these doors: either an 'inset hinge' or an 'offset hinge'. The inset type comes in a number of different styles, but is basically a hinge that is mostly hidden behind the overlap of the door face, as in the diagram above. The offset hinge is mounted on the face of the door, and looks like these ones...  And yep, been reading up on it a bit lately, for a project I'm involved in.    To get a good rounded edge on the face of the door, the easiest way to do it is on a bench-mounted router. If you don't have that equipment, humpyboy's method using a plane and sandpaper is the handywoman's alternative.  cheers, Al. |

|

|

|

Post by humpyboy on Mar 16, 2012 20:40:01 GMT 10

Just a tad more involved than I thought Al, can you explain the reason for the double skin?

|

|

|

|

Post by Franklin1 on Mar 16, 2012 22:58:55 GMT 10

I think it's just a method of saving weight. You need the cupboard door to "insert" into the frame by a certain amount so the catch can be positioned appropriately, and the easiest way to make a door that does this, and which is also lightweight, is via the "drum built" method.

I've seen some doors on normal kitchen cupboards that have the insert section made out of solid ply (or chipboard or other timber), but they are noticeably heavy. When you look at old wardrobes in the Op Shops, the ones made in the 1950s are pretty lightweight and have doors made with the drum built technique. Seems like the same idea was applied to the old caravans as well.

cheers,

Al.

|

|

|

|

Post by seeshell on Mar 17, 2012 2:07:19 GMT 10

Hi Franklin To add a bit more about the doors, ours are made of probably no more than 6mm ply with the corners rounded over as you say. This thin external layer effectively lays right on the cabinet carcass. The offset is provided by one vertical and one horizontal piece of wood, configured in a "T" shape, with the top along the hinge edge. These battens are glued to the inside of the door; the hinge and the catch are applied to them and sit into the opening of the frame, without protruding into the cupboard space. We don't have an internal skin. Ignore the poor (now replaced!) wiring - you can see the battens on the back of the very thin door in this shot:  Very light, but very sturdy! Cheers Seeshell |

|

|

|

Post by Franklin1 on Mar 17, 2012 9:22:31 GMT 10

G'day seeshell, Yep, there's certainly a number of different ways of making these doors. I guess if you ran a competition to determine how to make the lightest door, or how to make one with the least amount of timber, then your style would be a front runner.  I've seen doors where the outer face is made of two layers of timber...a 1/8" layer of masonite bonded to a 1/8" layer of ply. The smooth surface of the masonite gives a nice surface for gloss paint, and the plywood backing reduces the overall weight a bit. I think the inner plywood skin is probably used more for scoring extra marks for "neatness and appearance". Although having said that, if the outer skin is plywood, there is the possibility of the face warping/bowing over time, and an inner skin would be necessary to prevent that happening. cheers, Al. |

|

|

|

Post by cobber on Mar 17, 2012 9:56:23 GMT 10

I thought the cupboard doors on my Newcastle van were pretty minimalistic seeshell but... I agree with Al...........yours take the cake. Mine have a frame all the way around the perimeter which I assumed would be necessary to prevent warping ….... yours haven't warped ?  One of the secrets, I have been told, to prevent warping is to make sure both sides of the ply/Masonite are painted. On the larger wardrobe doors they have gone for double skin in the Newcastle van.... but have stuck with single skin in my “Driftwood” van with frame around the perimeter and one piece of framing timber across the middle...... that door hasn't warped yet..... fifty years + later. Newcastle van Wardrobe.  So it sort of boils down to.... do you want a light door or.... a tidy door, because warping doesn't seem to be a problem with either method of construction. As for hilldweller's question.............. I think humpyboy might have nailed that in the first reply   Cobber. |

|

|

|

Post by humpyboy on Mar 17, 2012 10:17:54 GMT 10

As for hilldweller's question.............. I think humpyboy might have nailed that in the first reply   Cobber. This was exactly the style I was thinking of when I posted my reply but had no picture, Thanks Cobber |

|

|

|

Post by Franklin1 on Mar 17, 2012 10:33:22 GMT 10

Sooo...are there any caravan WARDROBE doors out there that are just the external facing with perimeter framework, but NO internal skin? Got any photos of your naked doors??   |

|

|

|

Post by cobber on Mar 17, 2012 12:26:55 GMT 10

G'day Al. This is a photo of “Driftwoods” single skin plywood wardrobe door, still fits snugly.  But...... but, if you want light...strong...and beautiful, this is the way to go I reckon. Janaway II   The inner curvy plywood layer is glued to the outer skin.... both of them three ply. Cobber. |

|

|

|

Post by seeshell on Mar 17, 2012 13:09:27 GMT 10

Hi Al and Cobber Mine have a frame all the way around the perimeter which I assumed would be necessary to prevent warping ….... yours haven't warped ?  Nope, straight as a can be. One of the secrets, I have been told, to prevent warping is to make sure both sides of the ply/Masonite are painted. I imagine this would be to seal up the masonite and prevent it taking on moisture, so it doesn't swell or rot? Cheers Seeshell |

|

|

|

Post by seeshell on Mar 17, 2012 13:14:09 GMT 10

Hi Al

Our wardrobe doors also have only battens, just like the cupboard doors.

No warping or issues with them.

Cheers

Seeshell

|

|

|

|

Post by Franklin1 on Mar 17, 2012 13:28:18 GMT 10

Gees cobber, that Janaway II door is certainly a work of art!    And to think all that creative woodwork is hidden away on the inside of the door?! Struth, and we haven't even talked about caravan ENTRANCE doors yet. This thread could go on for like, ummm, two days more at least!!   seeshell, yeah painting timber on all sides helps to seal it from moisture. It would be particularly helpful in those cupboards that are in close proximilty to the cooking area where steam is generated. Or wherever the jug is boiled on a regular basis.  cheers, Al. |

|

|

|

Post by Don Ricardo on Mar 17, 2012 22:02:43 GMT 10

Hi all, All the cupboard doors and the wardrobe door on our van are single skin and constructed using the same method as the doors on Cobber's Newcastle van.   The cupboard doors are all painted on both sides, while the wardrobe door is varnished inside. None of them have warped, however, the ply appears to be quite a bit thicker than that on the Newcastle - at least 5 ply:  There are two types of hinges used. The cupboard doors use hidden, rebated hinges:   The drop down doors on the overhead lockers use visible, external hinges like the ones Franklin1 showed:  Don Ricardo |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 17, 2012 22:58:47 GMT 10

Janaway II   that door is bloody bewdiful  Cobber ......any chance of mounting the frame on the front of the door, relocate the latch and hinges, and reverse the door ;D ;D |

|

|

|

Post by hilldweller on Mar 19, 2012 17:48:58 GMT 10

Blimey! Just as well I asked. Very interesting replies thank you all, and especially for the pics. Since I want light, non-warping and, most importantly, achievable, I'm thinking something along the lines of Cobber's Newcastle picture, with hinges as per Seeshell's (but modern copies). As for screws, well I'm on the trail of some slot head screws for the table edge so will see what I can do. I'll investigate a sheet of hardboard/masonite next time I'm at one of the big shed places. I would really like to get the wardrobe door done for the Easter trip but the rest will have to wait until I have more time.

|

|